To ensure your snowblower and other small engines stay working in tip top shape it is important to ensure that repairs and maintenance are done frequently but also that you lubricate your small engine. If you prefer a hands off approach, we can do this for you during your small engine tune up in Ottawa or you can tackle the task of lubricating your snowblower – don’t worry it’s pretty easy.

Grease the axle shafts

It’s important to grease the axle shafts because if you forget to do it then the wheel could be permanently stuck to the axle which is not good.

Moisture and ice-melting agents like salt make contact with your snow blower causing corrosion and rust which will build up over time between the wheel hubs and the axles. Without being periodically cleaned and properly lubricated, they can rust together. If a wheel is permanently fused to its axle, accessing the hardware to remove the bottom cover on the unit will be a very inefficient and unpleasant experience and almost always results in a trip to the hardware store to buy a new snow blower.

The good news is that lubricating the axle shafts is simple. All you have to do is remove each wheel from the axle and check to see if rust is present on the axles. If you find rust then remove it with sandpaper, wipe clean and coat with a thin to medium layer of grease. It is also a good idea to clean and lubricate the axle ends where the snap clips are secured to because just like the wheel and axle, if neglected, the snap clips can also rust to the axle and prevent wheel removal.

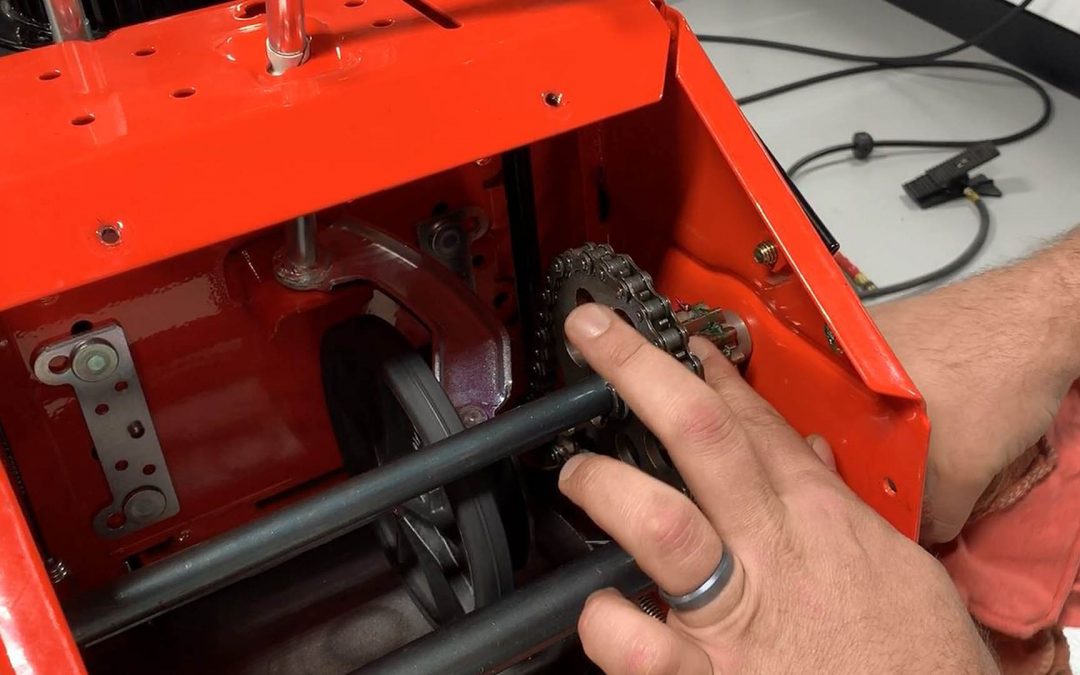

Lubricate snow blower tractor components

If you find that some parts aren’t moving such as the shift lever on your snow blower, this could be caused by the components in the snowblower not being lubricated and eventually rusting together.

Your snow blower is designed for the rugged outdoors however your snow blower small engine is not water tight. Moisture from the elements will get into the frame. In order to preserve the mobility of critical moving parts inside the frame you must perform routine maintenance with regular lubrication of these components. Though that part of the machine may seem intimidating, accessing those components is extremely easy. Simply remove the bottom cover from the snow blower and perform the following procedures as directed in your operator’s manual:

- Apply grease to the hex shaft so the friction disc can slide along it easily.

- Apply grease to the gears

- Apply a thin layer of oil to the chain and wipe clean

- Pump grease into the pinion shaft (grease fitting located outside frame)

Lubricate snow blower augers

Bust an auger? Throw a shear bolt? Want to not damage the auger gearcase if you hit a rock? If you said yes to any of those, the augers will need to be lubricated so they can spin freely on the auger shafts.

Applying grease to the augers is easy. Remove the shear bolts from each auger, pump grease into the grease fittings on the auger shaft and manually turn the auger by hand to spread grease along the auger shafts. When complete, reinstall the shear bolts and torque to the specification listed in the operator’s manual.

Following these lubrication tips for your snowblower small engine and you will have a worry free and easy time clearing snow throughout the entire season. If you would like us to perform some routine small engine maintenance or small engine repairs just give us a call and we will be happy to help with all of your small engine needs and servicing in the greater Ottawa region.